The Goldsmithy design and create custom made watches from their Stony Stratford workshop.

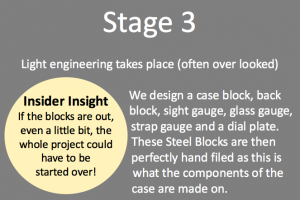

Having specialised in hand making watch cases during his small worker apprenticeship, Glenn learnt to understand the need for precision. Due to the intricate working parts of a watch movement the case needs to be airtight to prevent dust clogging and wear and tear. With this in mind a small worker has to file to “a quarter of a thou” or a tenth of a millimetre. This requires skill, patience and a lot of pre planning in the design stages.

In the world of precious metals, watch case making is considered one of the highest skill levels due to the time taken to reach the perfection needed for workability and continuation of the tradition.

A watch can take up to a year to make due to the collaboration of workers involved.

Here’s a few of the stages in pictures…